Description

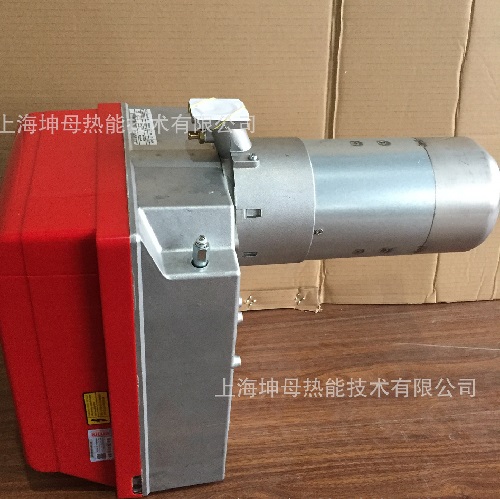

RIELLO RS44 TC two-stage gas burner for commercial boiler

-

Monoblock forced draught gas burner with two stage operation, fully automatic, made up of:

– Air suction circuit with sound proofing material

– High performance fan with straight blades

– Air damper for air flow setting and butterfly valve for regulating fuel output on 1st and 2nd stage controlled by a servomotor with variable cam

– Starting motor at 2800 rpm, single-phase / 220-230V / 50-60Hz or three-phase / 380-400V / 50-60Hz

– Combustion head, that can be set on the basis of required output, fitted with:

– stainless steel end cone, resistant to corrosion and high temperatures

– ignition electrodes

– ionisation probe

– gas distributor

– flame stability disk

– Exclusive patented HCS (Housing Cooling System) with high thermal insulation and air circulation with continuous

air volume refresh for an active cooling system and avoid heat transfer to the electrical component housing

– Minimum air pressure switch stops the burner in case of insufficient air quantity at the combustion head

– Microprocessor-based burner safety control box, with diagnostic functions

– Plug and socket for electrical connections accessible from the external of the cover

– Burner on/off selection switch

– 1st – 2nd stage manual switch

– Flame inspection window

– Slide bars for easier installation and maintenance

– Protection filter against radio interference

– IP X0D (IP 40) electric protection level.

-

Standard equipment

– 1 gas train flange

– 1 flange gasket

– 4 screws for fixing the flange

– 1 thermal screen

– 4 screws for fixing the burner flange to the boiler

– 3 plugs for electrical connection (RS 34 – 44 MZ single-phase)

– 4 plugs for electrical connection (RS 44 MZ three-phase)

– Instruction handbook for installation, use and maintenance

– Spare parts catalogue.

Riello RS44 TC two stage gas burner

Overview

The RS burners series covers a firing range from 44 to 2290 kW, and it has been designed for use in low or medium temperature hot water boilers, hot air or steam boilers, diathermic oil boilers.

Operation is “two stage progressive”, the burners are fitted with a microprocessor-based burner safety control box which supplies indication of operation and diagnosis of fault cause.

The elevated performance of the fans and combustion head, guarantee flexibility of use and excellent working at all firing rates. The exclusive design ensures reduced dimensions, simple use and maintenance.

Optimisation of sound emissions is guaranteed by the special design of the air suction circuit and by incorporated sound proofing material. A wide range of accessories guarantees elevated working flexibility.

WhatsApp +8613906047998

WhatsApp +8613906047998